< Previous | Contents | Next >

Annex 2-2 Guidance for non-destructive examination of marine steel castings

1. Application

(1) The requirements in this Guidance is intended to give general guidance on the extent, methods and recommended quality levels applicable to the non-destructive examinations (NDE), of marine steel castings(hereinafter referred to as "castings") specified in Pt 2, Ch 1, 501. 8 and

10 of the Rules, except in those cases where alternative criteria have been otherwise approved or specified.

(2) Although no detailed Guidance are given for machinery components, the requirements in this Guidance may apply correspondingly considering their materials, kinds, shapes and stress con-

ditions being subjected.

2. Personnel Requirements

(1) Personnel carrying out NDE are generally to be qualified and certified to Level II of a recog- nised certification scheme such as K S B ISO 9712, SN T -T C -1A , E N 473, A SN T C entral Certification P rogram (AC CP ) or equivalent.

(2) Personnel responsible for the NDE activity including approval of procedures should be qualified and certified to Level III.

(3) Personnel qualifications are to be verified by certification.

3. Casting Condition

(1) Non-destructive examinations applied for acceptance purposes should be made after the final heat treatment of the casting. Where intermediate inspections have been performed the manufacturer shall furnish the documentation of the results upon request of the Surveyor.

(2) Castings are to be examined in the final delivery condition free from any material such as scale, dirt, grease or paint that might affect the efficacy of the inspection. A thin coating of contrast paint is permissible when using magnetic particle techniques.

(3) Unless otherwise specified in the order, magnetic particle test shall be carried out within 0.3 mm of the final machined surface condition for A C techniques or within 0.8 mm for D C techniques.

(4) Ultrasonic testing is

to be carried out after the castings have been ground, machined or shot

blasted to a suitable condition. The surfaces of castings to be examined should be such that ad-

equate coupling can

be established between the probe and the casting and that excessive wear

of the probe is avoided.

4. Extent of Examinations

(1) Castings to be examined

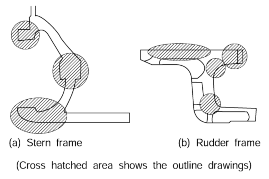

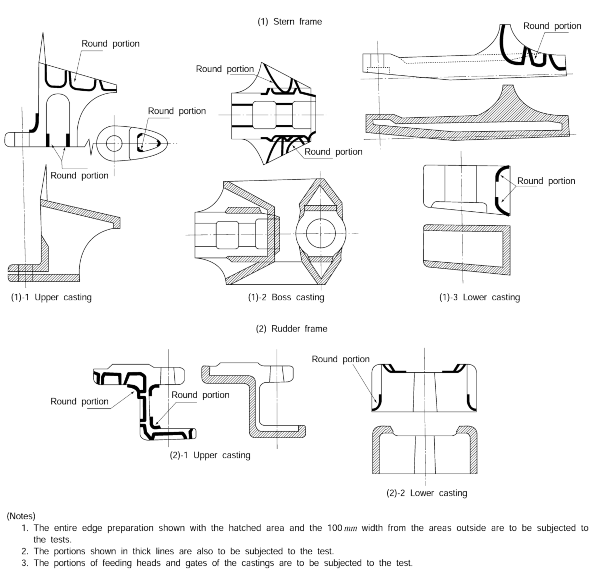

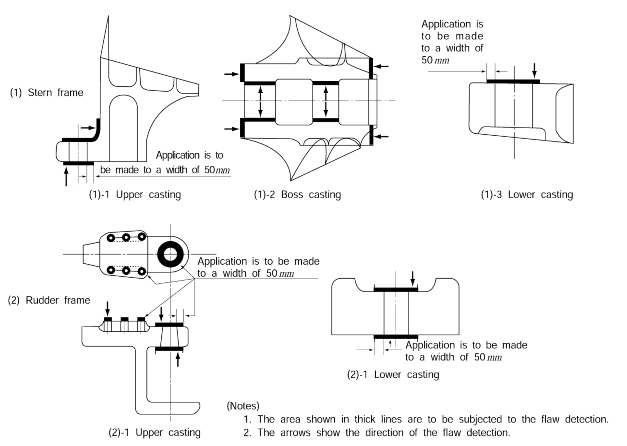

Castings to be examined by NDE methods are identified in Fig 1 to Fig 3 of this Guidance. Criteria for the examination of other castings not identified in Fig 1 to Fig 3 of this Guidance will be subject to agreement.

(2) Zones to be examined

(A) Zones to be examined in nominated castings are identified in Fig 1 to Fig 3 of this Guidance. Examinations are to be made in accordance with an inspection plan approved by the Society. The plan should specify the extent of the examination, the examination proce-

dure, the quality level or, if necessary, level for different locations of the castings.

(B) In addition to the areas identified in Fig 1 and Fig 2 of this Guidance, surface inspections

shall be carried out in the following locations:

(a) at all accessible fillets and changes of section,

(b) in way of fabrication weld preparation, for a band width of 30mm,

(c) in way of chaplets,

(d) in way of weld repairs,

(e) at positions where surplus metal has been removed by flame cutting, scarifying or

arc-air gouging.

(C) Ultrasonic testing shall be carried out in the zones indicated in Fig 1 and Fig 3 of this Guidance and also at the following locations:

(a)

(b)

(c)

in way of all accessible fillets and at pronounced changes of section,

in way of fabrication weld preparations for a distance of 50 mm from the edge,

in way of weld repairs where the original defect was detected by ultrasonic testing.

(d)

in way of

riser positions,

![]()

Guidance Relating to the Rules for the Classification of Steel Ships 2015 49

![]()

(e) in way of machined areas particularly those subject to further machining such as bolt hole positions.

Fig 1 Detection Area for Non-destructive Test

Fig 2 Example of Application of Magnetic Particle Tests

![]()

50 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()

Fig 3 Examples of Application of Ultrasonic Tests

5. Examination Procedures

(1) Visual Inspection

Steel castings nominated for NDE shall be subjected to a 100% visual examination of all acces- sible surfaces by the Surveyor. Lighting conditions at the inspected surfaces shall be in accord- ance with a nationally or internationally recognised standard. Unless otherwise agreed, the visual and surface crack detection inspections are to be carried out in the presence of the Surveyor.

(2) Surface Crack Detection

(a) Magnetic particle inspection will be carried out in preference to liquid penetrant testing ex- cept in the following cases;

(i) austenitic stainless steels,

(ii) interpretation of open visual or magnetic particle indications,

(iii) at the instruction of the Surveyor.

(b) The testing procedures, apparatus and conditions of magnetic particle testing and liquid pene- trant testing other than those specified in this Guidance are to comply with recognised na- tional or international standards.

![]()

![]()

(c) Magnetic particle testing is to be carried out along two directions so that magnetic field can be directed at an right angle each other by means of the wet prod methods or the yoke m20e0tho3d0.0 Imnmm. aTkhineg mmaaggnneetitzizinagtiocnurbreyntthies ptorodbemDethCod8, 0t0he12d0is0taAnceforbetthweeepnropdromdsethisodt.o Fboer

the yoke method, lifting power is to be 4.5 kg for A C , 18 kg over for D C .

(d) For magnetic particle testing attention is to be paid to the contact between the casting and

the clamping devices of stationary magnetisation benches in order to avoid local overheating or burning damage in its surface. Prods shall not be permitted on finished machined items. Note that the use of solid copper at the prod tips must be avoided due to the risk of cop-

per penetration.

![]()

Guidance Relating to the Rules for the Classification of Steel Ships 2015 51

![]()

(e) When indications have been detected as a result of the surface jection is to be decided in accordance with Art 6.

(3) Ultrasonic testing

inspection, acceptance or re-

(a) Volumetric inspection in accordance with these guidance is to be carried out by ultrasonic testing using the contact method with straight beam and/or angle beam technique. The test-

ing procedures, apparatus and conditions of ultrasonic testing are to comply with the recog- nised national or international standards. Radiographic testing may be carried out on the ba- sis of prior agreement with the Society.

(b)

(c)

(d)

(e)

Only those areas shown in the agreed inspection plan need to be tested. The plan should include those locations nominated in 4. (2), (c) together with the scanning zones identified

for the relevant casting in Fig 1 to Fig 3.

Ultrasonic scans are to be made using a normal probe of 1~4 MHz (usually 2 MHz)

frequency. Whenever possible scanning is to be performed from both surfaces of the casting and from surfaces perpendicular to each other.

The back-wall echo obtained on parallel sections should be used to monitor variations in

probe coupling and material attenuation. Any reduction in the amplitude of the back-wall echo without evidence of intervening defects should be corrected. Attenuation in excess of 30dB could be indicative of an unsatisfactory annealing heat treatment.

Machined surfaces, especially those in the vicinity of riser locations and in the bores of stern boss castings, should also be subject to a near surface (25 mm) scan using a twin

crystal 0o probe. Additional scans on machined surfaces are of particular es where bolt holes are to be drilled or where surplus material such as

removed by machining thus moving the scanning surface closer to

importance in cas- 'padding' has been

possible areas of

shrinkage. Also, it is advisable to examine the machined bores of castings using circum- ferential scans with 70° probes in order that axial radial planar flaws such as hot tears can be detected. Fillet radii should be examined using 45°, 60°, or 70° probes scanning from

the surfaces/direction likely to give the best reflection.

(f) In the examinations of those zones nominated for ultrasonic examination the reference sensi-

tivity is to be established against a 6mm diameter disk reflector. Sensitivity

brated either against 6mm diameter flat bottomed hole(s) in a reference block blocks) corresponding to the thickness of the casting provided that a transfer

can be cali-

(or series of correction is

made, or, as a preferred alternative, by using the DG S (distance-gain-size) method. The DGS diagrams issued by a probe manufacturer identify the difference in dB between the ampli-

tude of a back wall echo and that expected from a 6mm diameter disk reflector. By adding this difference to the sensitivity level initially set by adjusting a back wall echo to a refer-

ence height eg 80 %, the amended reference level will be representative of a 6mm diameter disk reflector. Similar calculations can be used for evaluation purposes to establish the dif- ference in dB between a back wall reflector and disk reflectors of other diameters such as 12 or 15 mm.

(g) Having made any necessary corrections for differences in attenuation or surface condition be- tween the reference block and the casting any indications received from the nominated zones

in the casting that exceed the 6mm reference level should be marked for evaluation against the criteria given in 6. (3) below. Evaluation should include additional scans with angle probes in order that the full extent of the discontinuity can be plotted.

6. Acceptance Criteria

(1) Visual Testing

(a) All castings shall be free of cracks, crack-like indications, hot tears, cold shuts or other in- jurious indications. Thickness of the remains of sprues or risers is to be within the casting dimensional tolerance.

(b) Additional magnetic particle, dye penetrant or ultrasonic testing may be required for a more detailed evaluation of surface irregularities at the request of the Surveyor.

(2) Surface Crack Detection

(A) The following definitions relevant to indications apply:

(a)

(b)

(c)

Linear indication : an indication in which the length is at least three times the width.

Non-linear indication : an indication of circular or elliptical shape with a length less than three times the width.

Aligned indication : three or more indications in a line, separated by 2 mm or less edge-to-edge.

![]()

52 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()

(d) Open indication : an indication visible after removal of the magnetic particles or that can be detected by the use of contrast dye penetrant.

(e)

(f)

Non-open indication : an indication that is not visually detectable after removal of the

magnetic particles or that cannot be detected by the use of contrast dye penetrant. Relevant indication : an indication that is caused by a condition or type of discontinuity that requires evaluation. Only the indications which have any dimension greater than 1.5

mm shall be considered relevant.

(B) For the purpose of evaluating indications, the surface is to be divided into reference band length of 150 mm for level MT1/PT1 and into reference areas of 225 cm2 for level MT2/PT2. The band length and/or area shall be taken in the most unfavourable location rel- ative to the indications being evaluated.

(C) The following quality levels recommended for magnetic particle testing (MT) and/or liquid penetrant testing (PT) are;

Level MT1/PT1 - fabrication weld preparation and weld repairs.

Level MT2/PT2 - other locations nominated for surface crack detection in Fig 1 and Fig 2

The allowable numbers and sizes of indications in the reference band length and/or area are given in Table 1. The required quality level should be shown on the manufacturer's in- spection plan. Cracks and hot tears are not acceptable.

Table 1 Allowable number and size of indications in a reference band length/area

Quality Level | Max. number of indications | Type of indication | Max. number for each type | Max. dimension of single indication, (mm)(2) |

MT1/PT1 | 4 in 150 mm length | Non-linear Linear Aligned | 4(1) 4(1) 4(1) | 5 3 3 |

MT2/PT2 | 20 in 22500 area | Non-linear Linear Aligned | 10 6 8 | 7 5 5 |

Notes: (1) 30 mm min. between relevant indications. (2) In weld repairs, the maximum dimension is 2 mm. | ||||

(3) Ultrasonic testing

(A) Acceptance criteria for ultrasonic testing are identified in Table 2 as UT1 and UT2. As stated in 4 (2), (a), the quality levels applicable to the zones to be examined are to be identified on an inspection plan. The following quality levels are nominated for the castings identified in Fig 1 and Fig 3.

(B) Level UT1 is applicable to:

(a)

(b)

(c)

(d)

fabrication weld preparations for a distance of 50 mm,

50 mm depth from the final machined surface including bolt holes and fillet radii to a depth of 50 mm and within distance of 50 mm from the radius end,

castings subject to cyclic bending stresses e.g. rudder horn, rudder castings and rudder

stocks - the outer one third of thickness in the zones nominated for volumetric exami- nation by Fig 1 and Fig 3.

discontinuities within the examined zones interpreted to be cracks or hot tears.

(C) Level UT2 is applicable to:

(a) other locations nominated for ultrasonic testing in Fig 1 and Fig 3 or on the inspection plan.

(b) positions outside locations nominated for level UT1 examination where feeders and gates have been removed

(c) castings subject to cyclic bending stresses - at the central one third of thickness in the

zones of nominated for volumetric inspection by Fig 1 and Fig 3.

![]()

Guidance Relating to the Rules for the Classification of Steel Ships 2015 53

![]()

(D) Ultrasonic acceptance criteria for other casting areas not nominated in Fig 1 and Fig 3 will

be subject to special consideration based on the anticipated stress levels and and position of the discontinuity.

the type, size

![]()

![]()

Table 2 Ultrasonic Acceptance Criteria for steel castings

Quality Level | Allowable disc shape according to DG S(1) (mm) | Max. number of indications to be registered(2) | Allowable length of linear indications (mm)(3) |

UT1 | 6 | 0 | 0 |

UT2 | 12-15 15 | 5 0 | 50 0 |

Notes: (1) DG S: distance-gain size. (2) grouped in an area measuring 300 x 300 mm (3) measured on the scanning surface | |||

7. Reporting

(1) All reports of non-destructive examinations should include the following items;

(a)

(b)

(c)

(d)

(e)

(f)

Date of testing.

Names and qualification level of inspection personnel. Type of casting.

Product number for identification.

Grade of steel. Heat treatment.

(g) Stage of testing.

(h) Locations for testing.

(i)

(j)

(k)

(l)

Surface condition. Test standards used.

Results.

Statement of acceptance / non-acceptance.

(m) Locations of reportable indications.

(n) Details of weld repairs including sketches.

(2) In addition to the items listed in 7 (1), reports of surface crack detection inspections clude at least the following items:

(a) for liquid penetrant testing; the consumables used,

are to in-

(b) for magnetic particle testing: method of magnetising, test media and magnetic field strength.

(3) In addition to the items listed in 7 (1), reports of ultrasonic inspection should include at least the following items:

(a) flaw detector, probes, calibration blocks and couplant used.

8. Rectification of Defects

(1) General

(a) Defects and unacceptable indications must be repaired as indicated below.

(b) In either case where, after removing defects, the steel castings are used as they are or re- pair welding are carried out approval of the surveyor is to be obtained. In case where the depth of the recess after removing the defects is not larger than 15 mm (or 10 % of the

thickness of the steel castings, whichever is smaller) and the length is not more than 100

mm, the steel castings may be used without repair welding.

(2) Rectification of Defects

Defective parts of material are to be completely removed either by grinding, or by chipping and grinding, or by arc air-gouging and grinding and to be repaired by either of the following methods. Thermal methods of metal removal should only be allowed before the final heat

treatment.

![]()

54 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()

(A) In case of no repair welding being carried out

The portions required no repair welding after removing defects, are to be finished with a grinder etc. in accordance with the following:

(a)

All grooves shall have a bottom radius of approximately three times the groove depth.

(b)

Grooves and

configuration.

their vicinity are to be finished smoothly avoiding abrupt changes in

(c)

The portions where defects have been removed are to be verified that they are free

from harmful

defects by liquid penetrant test or magnetic particle test after finishing of

the surface configuration.

(B) The portions required repair welding are to be suitably shaped and verified that they are free from harmful defects by nondestructive tests specified in (2) (A) (c) above and also re-

paired in accordance with the requirements in 3. of this Appendix. Weld repairs should be suitably classified as follows.;

(a) Major repairs

(i) where the depth is greater than 25 % of the wall thickness or 25 mm whichever is

less,

(ii) where the total weld area on a casting exceeds 2 % of the casting surface noting that where a distance between two welds is less than their average width, they are

to be considered as one weld.

(iii)Major repairs require the approval of the Society before the repair is carried out.

The repair should be carried out before final furnace heat treatment.

(b) Minor repairs

(i) where the total weld area (length x width) exceeds 500 ![]()

(ii) Minor repairs do not usually require the approval of the Society but should be re-

corded on a weld repair sketch as a part of the manufacturing procedure documents.

These repairs should be carried out before final furnace heat treatment.

(c) Cosmetic repairs

(i) all other welds.

(ii) Cosmetic repairs do not require the approval of the Society but should be recorded on a weld repair sketch. These repairs may be carried out after final furnace heat

treatment but are subject to a local stress relief heat treatment.

(3) Procedure of repair welding

The procedure of repair welding is to be as follows.

(A) Welders

Welders intended to engage in repair work by welding are to pass the qualification tests of the Society.

(B) Welding consumables

The welding consumables are to be either low hydrogen type approved by the Society or those deemed equivalent.

(C) Preheating

(a) In cases where the carbon equivalent of the steel castings exceeds 0.44 %, the portions of repair welding and their vicinity are to be preheated to a temperature higher than

200°C. In this case, the carbon equivalent is to be calculated by the following formula.

![]()

![]()

(b) Even in case where carbon equivalent is 0.44 % or less, preheating may be required taking into account the shape and size of the steel castings.

(D) Position of welding

The positions of welding are to be as given in the following Table 3 in general.

![]()

Guidance Relating to the Rules for the Classification of Steel Ships 2015 55

![]()

Table 3 Position of Welding

Position welding Kind | Flat | Vertical | Horizontal | Overhead |

Manual welding |

|

|

|

|

Semi-automatic welding |

|

|

|

|

(E) Post weld heat treatment

(a) Post weld heat treatment may be exempted in the following cases, provided that the

carbon equivalent does not exceed 0.44 %.

(i) In case where the depth of chipping after the removal of defects is not more than 25 mm (or 20 % of the thickness, whichever is smaller) and the length is not more than 200 mm.

![]()

(ii) In cases where the depth of chipping after the removal of defects is not more than 15 mm and also the area is not more than 250,000

(b)

![]()

![]()

![]()

Pbeost5w50eld h6e5a0t treatnmdentht eispteoriobde icsartroiedbeountotinlefsusrntahcaens. oTnehehhooulrdipnegr teevmepryera2tu5rme mis otof welding depth. In case where annealing in furnace is impossible depending on the final condition of the steel castings to be finished, etc. or where the welding depth is not more than 50 mm as well as the length is not more than 300 mm, partial post weld heat treatment may be accepted as an alternative. By the partial post weld heat treat- ment, the welded portions and their vicinity within 100 mm therefrom are to be heated to a temperature not lower than 600 and kept at the temperature in a period not less than 10 minutes per every 25 mm of the welding depth, and then to be cooled gradually.

(F) Finishing after repair welding

The portions repaired by welding are to be finished by grinding, etc. so that inspection can be available.

(G) Inspection after repair welding

Parts which are repaired should be examined by the same method

as at initial inspection as

well as by additional methods as required by

the Surveyor. ![]()

![]()

56 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()